Moving industrial-size quantities of materials by hand in a factory or warehouse can be challenging. It is possible to do it this way, although a much more efficient and hygienic way is via a vacuum conveying system.

What Is a Vacuum Conveying System?

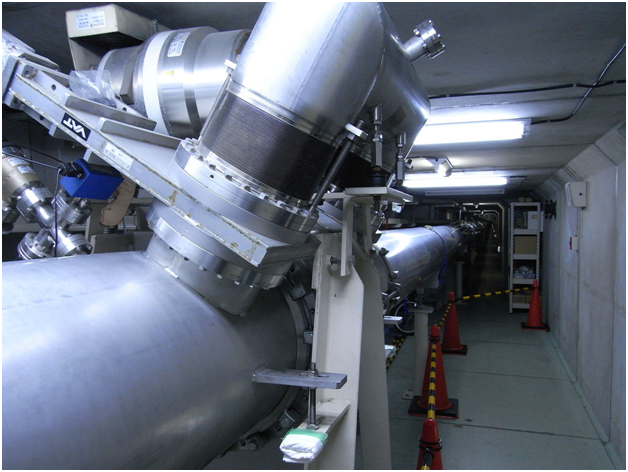

The basic principle of vacuum conveying is to move materials from a feed point to a delivery source. This is achieved when materials are introduced to an air stream at an optimal solid-to-air ratio. The air pressure created by a vacuum pump creates a high enough velocity for the material to be sucked through a system of tubes to its intended destination.

Who Uses a Vacuum Conveying System?

The use of a vacuum conveyor is popular in the food, fine chemical and pharmaceutical industries. Vacuum conveying is well suited to transporting salt, flour, sugar, water, spices, starch, glucose, yeast granules, talc, chemicals, paracetamol and plastics.

Why Use a Vacuum Conveying System?

A vacuum conveying system has a number of benefits to food, drug or chemical producers. They allow materials to be transported in a dust-free environment, ensuring there is no contamination. The process is highly efficient and cost-effective with very little manpower or maintenance needed. Even if a leak does occur, no hazardous material can escape due to the high pressure inside the conveyor. The machinery is both quiet and reliable and is relatively easy to install. Vacuum conveyors also help companies save space within their facility, as the pipe network can be placed on walls and within ceiling cavities. For more information on vacuum conveyors, visit sites such as http://www.aptech.uk.com/pneumatic-conveying/vacuum-conveying/.

Other Types of Systems

As well as vacuum conveying systems, a lot of industries also use mechanical conveying systems. A mechanical system includes a drive motor that creates enough energy to move the conveyor which is in direct contact with the material. This system can be either opened or closed to the outside environment and has a number of moving parts. Mechanical conveyors are well suited for heavy granular materials that may be moist, doughy and packable and unsuitable for transfer via a vacuum system. It is mainly wet sand, heavy material, crushed rock and large food particles that are transferred by mechanical means. The type of material that needs to be transported will determine which system of conveying is chosen.